[vc_row][vc_column][vc_column_text]

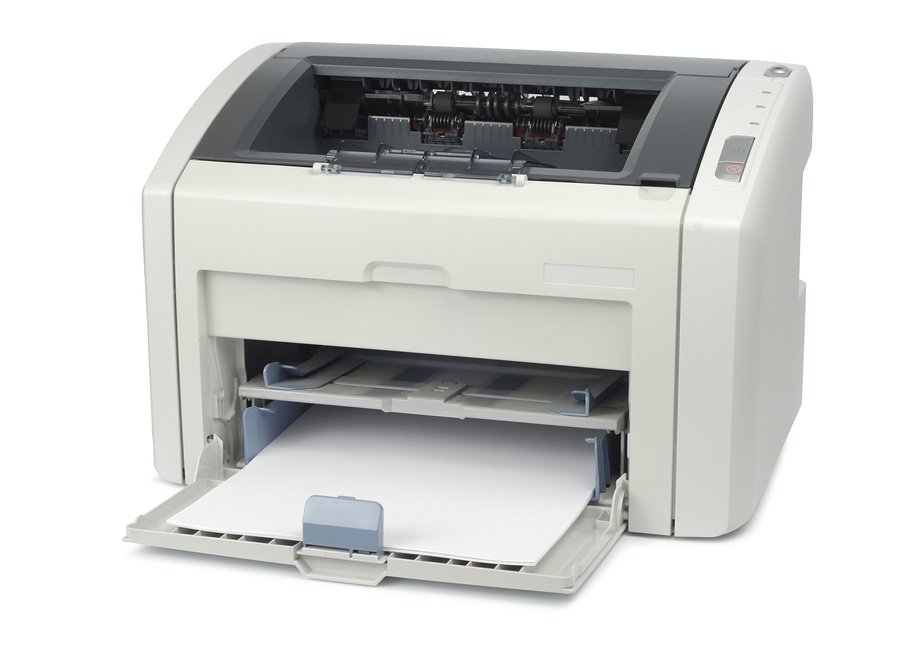

Paper jams can bring your productivity to a screeching halt. By taking some simple steps, you can significantly reduce the number of laser printer paper jams you experience on a regular basis. Depending on the printer, you might even go years at a time without having to fight another paper jam while processing print jobs.

Paper jams can bring your productivity to a screeching halt. By taking some simple steps, you can significantly reduce the number of laser printer paper jams you experience on a regular basis. Depending on the printer, you might even go years at a time without having to fight another paper jam while processing print jobs.

-

- Use the paper guides. Each printer comes with a set of guides where you place the fresh paper in the input tray. Laser printers that have a document feeder for scanning papers also have paper guides. The paper guides should always be slid against the margins of the paper, so they can guide the paper into the machine straight. Do not push the guides against the paper’s margins so the paper bows or creases, though, since that can also lead to jams.

- Use the correct paper. Not all paper is designed to work in any kind of printer. Some papers are made only for laser printers, others are made only for ink jet printers and still other papers are made only for copiers and are not to be used in any kind of printer. Not only can using the wrong type of paper cause jams, but they can also cause your printouts to streak or even lead to the paper melting inside the printer.

- Clean the printer’s rollers.The rollers both at the openings in the printer, and also inside the printer’s casing, can accumulate paper dust and ink. This debris buildup eventually reaches the point that the rollers can no longer grab the paper as they should, and so the paper slips off the rollers. You can clean the rollers by rubbing a cotton swab dampened with rubbing alcohol or distilled water against the rollers while you spin them with your fingers. Always unplug the printer’s power cord before cleaning the rollers, avoiding the printer turning on by accident while you are working. How often you clean the rollers depends on how much you use the printer and how many pages you print, but figure an average printer needs its rollers cleaned about every three to four months.

- Do not use damaged paper in your printer.Paper damage can include paper with creases, tears, dog-eared corners or papers that have sticky or rough spots on them. Also, on some new reams of paper the pieces of paper stick to each other, which can cause more than one sheet to feed into the printer at a time. You should always flip through a stack of new paper before insert it into your printer’s input tray, separating the sheets and allowing you to look for problem sheets. If you find any paper that is damaged, remove it from the stack before you place it in the printer’s input tray, causing a jam.

- Do not overfill the print tray, or let the end tray become overfilled. Most printer input trays have a line marked on the inside of the tray, which designates the highest point paper should occupy inside the tray. Loading the paper in the tray higher than the line often results in paper jams. Similarly, printers can only hold so many printed sheets of paper in the output tray before creating a backlog that causes a jam.

- Do not mix paper types in the printer’s input tray. If you need to print on more than one type of paper, you need to run one print job with one type of paper, and then switch to the other type of paper. Mixing either the size or type of paper in the input tray means you cannot have the proper paper settings selected for both types of paper, which leads to jams.

If you are tired of printing maintenance, hire a managed print provider like Great Lakes Computer. Our Managed Printing Services Save Clients Money. Inefficient use of reproductive machines can cut into a company’s profitability. In fact, the majority of printing expenses are incurred after printers are already installed. At Great Lakes Computer, we specialize in saving our clients money with Managed Print Services. Let us know about your company’s printing needs, and we’ll tell you how we can help.

[/vc_column_text][/vc_column][/vc_row]